From the mill to the table, fortified wheat flour is changing lives across India. By adding iron, folic acid, and vitamin B12, Fortify Health is tackling anaemia at scale. Tools like iCheck ensure every bag delivers the right nutrients, by enabling quality checks at partner mills and turning innovation into impact

Anaemia remains highly prevalent in India, affecting women and children at alarming rates. According to the National Family Health Survey (2019–2021), 67% of children aged 6–59 months and 57% of women aged 15–49 years are anaemic (1). Anaemia can have severe consequences, including impaired growth and development in children, reduced productivity in adults, and increased risks during pregnancy (1). Addressing this challenge requires interventions that reach populations at scale, such as wheat flour fortification with iron, folic acid, and vitamin B12 (2).

To support this, the Food Safety and Standards Authority of India (FSSAI) introduced the Fortification of Foods Regulations in 2018. These guidelines specify dosage ranges for micronutrient addition in wheat flour and require fortified products to carry the “+F” logo (2). Although fortification is voluntary, manufacturers that choose to participate must comply with these standards (3). Robust quality assurance is essential to ensure that fortified flour consistently delivers its intended health impact. Tools like iCheck allow rapid nutrient testing and verify compliance, ensuring every bag of fortified flour meets national standards.

In this article, we explore how Fortify Health has scaled wheat flour fortification, upheld rigorous quality standards, and leveraged iCheck technology to reach millions of families across India.

Building Fortification for Scale

Fortify Health was founded in 2017. The team were particularly struck not only by the depth of the anaemia issue in India, but also by the evidence, scalability and cost-effectiveness of one solution to address anaemia: flour fortification. Today, Fortify Health facilitates fortification of wheat flour at scale in India by providing mills with a comprehensive, hassle-free bundle of services that makes it easy to adopt fortification.

evidence, scalability and cost-effectiveness of one solution to address anaemia: flour fortification. Today, Fortify Health facilitates fortification of wheat flour at scale in India by providing mills with a comprehensive, hassle-free bundle of services that makes it easy to adopt fortification.

“Fortification has already transformed public health once before, with salt iodization and vitamin-enriched oils,” notes Shriya Agarwal, Associate Director of Monitoring, Evaluation & Research at Fortify Health. “We believe wheat flour fortification can have the same transformative effect for iron deficiency in India.”

The organization’s growth has unfolded in two strategic phases. Phase one focused on establishing systems, determining optimal fortification dosages, and building relationships with millers. Phase two, launched in 2022, shifted toward scale through private sector and government partnerships.

Today, Fortify Health operates across 16 states with a strong presence in Madhya Pradesh, Gujarat and Haryana regions where wheat consumption is highest and word-of-mouth has proven most effective in encouraging mill partners to adopt fortification. Fortify Health is now reaching 10 million individuals per month with fortified wheat flour.

A Partnership Model That Works

What sets Fortify Health apart from larger organizations is its comprehensive, partner-centric support model. In India, Fortify Health collaborates with a diverse range of stakeholders including government agencies, quasi-governmental bodies, non-profits, and private

companies, to integrate wheat flour fortification into their programs, including social safety net programs that reach marginalized communities in India.

The organization offers end-to-end fortification support at no cost to mill partners, covering premix supply, microdoser installation, training, and ongoing quality monitoring. This approach directly addresses miller’s main concern that fortification, if done improperly, could reduce consumer demand or impact brand reputation. As such, Fortify Health ensures that fortification has effectively no impact on the look, smell or taste of the wheat flour received by customers. By eliminating financial barriers and providing technical guidance, Fortify Health builds trust while facilitating widespread adoption of fortification.

Beyond implementation, Fortify Health conducts rigorous monitoring, evaluation, and research to optimize impact, raise public awareness about the benefits of food fortification, and pilot innovative approaches.

The effectiveness of this model is evident in success stories such as Sanghvi Foods, a 900-ton-per-day mill in Indore, India. With Fortify Health’s support, which included high-quality premix, microdoser installation, staff training and regulatory guidance. Sanghvi Foods successfully reintroduced fortified wheat flour. For over 3 years, production has run smoothly, with no impact on taste, texture, or consumer acceptance, and plans to expand further (4). This demonstrates both the commercial viability and scalability of fortification when quality assurance is prioritized.

Building Trust Through Rigorous Quality Control

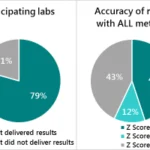

As Fortify Health scaled operations, ensuring consistent quality became both essential and challenging. The organization developed a multi-layered system to verify that fortified flour meets regulatory standards and delivers the intended nutritional benefits.

At the core of this system are two internal tests. The mill staff are trained to conduct iron spot tests, providing a quick, real-time check for the presence of iron in fortified flour. In addition, Fortify Health performs tests with iCheck Iron at least monthly for each partner mill. Beyond these internal checks, millers send flour samples to the National Accreditation Board for Testing and Calibration Laboratories (NABL) at least every six months, ensuring independent verification.

Integrating iCheck into Fortification

Despite these safeguards, technological limitations persisted. While sensor-based microdosers offered advanced technology, their accuracy depended heavily on proper calibration. At the same time, monthly lab testing, though precise, lacked the speed required for real-time quality control.

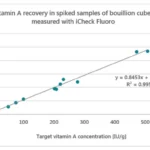

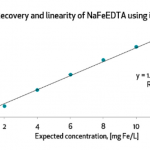

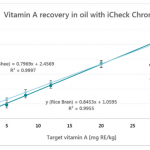

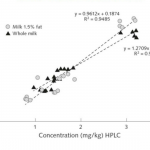

To bridge this gap, Fortify Health partnered in 2023 with BioAnalyt and the Centre for Rural Development and Technology (CRDT) at IIT Delhi to validate BioAnalyt’s iCheck iron, a rapid testing tool capable of measuring iron levels directly at mill sites, specifically in the Indian context.

The partnership’s impact was validated in 2025 with a peer-reviewed study by Sane et al., confirming that rapid quantification methods are reliable for fortified wheat flour (5). This evidence strengthened Fortify Health’s centralized quality control using iCheck.

Fortify Health uses the iCheck device at its two testing sites, where flour samples from partner mills are shipped for testing. Unlike the iron spot test, which provides a quick but less precise indication, iCheck offers quantitative results that confirm the actual iron content added. This strengthens quality control by ensuring fortified flour meets national standards.

Scaling Toward System Change

With validated technology and proven partnerships, Fortify Health is positioned for broader impact. The organization aims to expand beyond medium-sized mills (300-1000 MT/month) to engage larger mills, retail brands that outsource production, and new government partners, potentially reaching millions more consumers.

Simultaneously, Fortify Health is piloting consumer demand-generation campaigns to build market awareness and offering support to the national government to address anemia by scaling wheat flour fortification across India. What ’s more, the organization’s internal state assessment tool helps identify high-priority geographies based on agricultural and consumption patterns, ensuring resources are deployed strategically as operations expand.

Lessons for Regional Impact

Fortify Health’s model offers valuable insights for addressing micronutrient deficiencies. The organization’s experience demonstrates that effective fortification requires more than technical solutions. It demands partnership models that align incentives, government collaboration that ensures institutional reach, and quality assurance systems that can operate at scale.

As Fortify Health works toward its vision of “building a healthier world where everyone has the micronutrients they need to survive and thrive” its collaboration with BioAnalyt represents more than just a technological validation. It demonstrates how innovation partnerships can overcome implementation challenges while generating the evidence needed to inform policy. Through continued collaboration between innovators like BioAnalyt and implementers like Fortify Health, India is moving closer to a future where millions can live free from the burden of iron deficiency anaemia.

Read more about iCheck Iron Measuring Iron in Fortified Flour

References:

- Ministry of Health and Family Welfare (MoHFW), Government of India, UNICEF, & Population Council. (2019). Comprehensive National Nutrition Survey (CNNS) National Report 2016–2018. New Delhi: MoHFW.

- International Institute for Population Sciences (IIPS) & Ministry of Health and Family Welfare (MoHFW), Government of India. (2019). National Family Health Survey (NFHS-5), 2019-21. Retrieved from https://www.nfhsindia.org

- Food Safety and Standards Authority of India. (2018). Food Safety and Standards (Fortification of Foods) Regulations, 2018. Retrieved from https://www.informea.org/en/content/legislation/food-safety-and-standards-fortification-foods-regulations-2018

- Fortify Health. (2025, July 4). How Sanghvi Foods is fortifying wheat flour with Fortify Health | A mill’s experience [Video]. YouTube. https://www.youtube.com/watch?v=PCOpbiHfk88

- Sane, A., et al. (2025). Assessment of suitability of a rapid quantification method for determination of added iron content in fortified wheat flour: A method validation study. Food Chemistry, 463, 141626. https://www.sciencedirect.com/science/article/abs/pii/S088915752500626X