DOWNLOAD APPLICATION PAPER

Rice Fortification

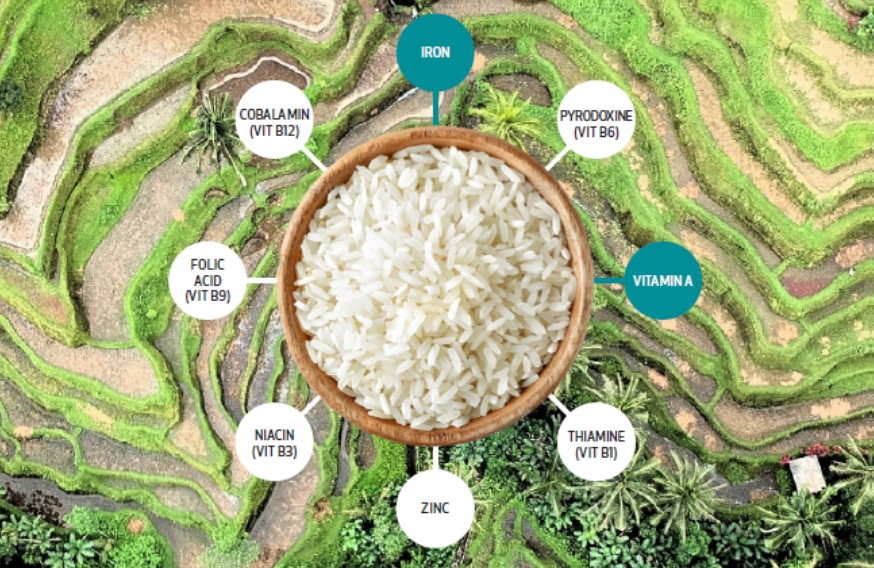

Over 3.5 billion people across Asia, Africa, and Latin America depend on rice for up to 20% of their daily calories. This rice, however, is most often polished to remove the outer bran layer, depriving it of its naturally occurring vitamins and minerals. People that rely on rice to supply the majority of their daily energy needs are thus at high risk of developing deficiencies in these micronutrients.

Due to its ubiquitous consumption, rice offers an excellent vehicle for delivering essential micronutrients through fortification. The cost of adding the recommended micronutrients to rice (e.g. iron, zinc, vitamin A, and B vitamins) amounts to less than US$ 1 annually per person, and can contribute to significant health and economic benefits, such as increased productivity and decreased disease burden.

Food fortification is generally a straightforward process: dry or liquid micronutrient premix is added for blending into a staple food, such as flour, salt, or oil, at a defined ratio. Production of fortified rice, however, is technologically more complex. One method involves dusting or coating rice with a micronutrient premix. A second method is cold or hot extrusion of fortified kernels (FK), which are blended into polished rice. Of these, hot extrusion technology is the most effective in retaining added micronutrients during storage and after the rice has been washed and cooked.

FK are made by mixing micronutrient premix with rice flour and then reconstituting the mix through extrusion to mimic a regular rice kernel. These fortified reconstituted kernels are blended in with regular rice at a ratio between 0.5%-2%, most frequently at 1%. A 1% blending ratio means that 1g of FK is added for every 99g of regular rice.

Additional costs to fortify rice with fortified kernels are context-specific. Based on experience in 15 countries, the retail price for fortified rice may rise between 1 and 10%. For example, in Mali, the additional cost of fortification adds up to US$ 2 per 100 kg of rice.

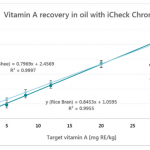

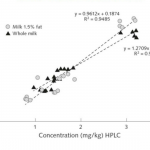

Measuring Iron and Vitamin A in Fortified Kernels with iChecks

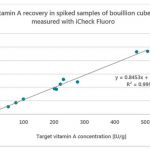

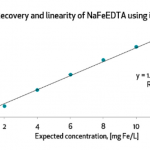

To support the implementation of rice fortification, BioAnalyt has partnered with DSM to develop and optimize a sample preparation method for FK. iCheck Iron is a portable, single-wavelength photometer, and iCheck Fluoro is a portable, single-wavelength fluorometer. Both are pre-calibrated for quantitative measurement of iron and vitamin A, respectively, in various food matrices, including many types of flour.

To ensure a reliable result with iCheck Iron and iCheck Fluoro, FK samples require a customized sample preparation protocol. First, the FK is ground into a fine, flour-like powder and digested with α-amylase, taka-amylase A, or taka-diastase enzymes. Enzymes help to break down the structure of extruded FK and release the iron and vitamin A for an efficient extraction into the reagent vial. Download our application paper here (updated version from 30.08.2019) to learn more.

As always, the BioAnalyt team is on standby to answer your technical questions, provide product support, or assist you with ordering iChecks and test kits. Contact us today!