We showcased two of our latest innovations in the pipeline – The iCheck Connect and iCheck Modular – at the World Food Program’s 51st innovation boot camp and pitch event in Munich last Friday. The event was organized as part of the WFP Innovation Accelerator program to support and scale up high-potential solutions to end hunger worldwide.

The WFP Innovation Pitch is a high-level hybrid event where various innovators and entrepreneurs showcase the latest advances in digital innovation, such as mobile technology, artificial intelligence, big data, and blockchain, as well as new business models to the private sector, donor agencies, and development partners. They also get a platform to demonstrate how their innovation can positively impact people’s lives.

According to WFP, as many as 30 million people in 82 countries face acute food insecurity. Given the enormity of the crisis, the need for innovations and technologies to fight hunger is all the more pertinent now.

The United Nations World Food Programme (WFP) Innovation Accelerator is dedicated to achieving zero hunger by sourcing, supporting, and scaling high-impact innovations. WFP offers entrepreneurs and startups hands-on support, funding, and access to WFP’s global operations and ensures that these projects are delivered with the maximum possible impact.

The BioAnalyt booth generated much interest among attendees who hoped that iCheck Modular could potentially substitute conventional laboratory techniques on several grounds, such as the significantly reduced cost, time, and effort for the testing procedures.

Our latest products are being developed to provide an all-inclusive on-site testing solution and an online data handling platform for improved digitalized Quality Assurance and Quality Control (QA/QC) processes in food fortification and beyond.

iCheck Modular is the next generation of hardware that leverages novel analytical solutions to enable rapid multiplexed testing of nutritional, safety, and quality parameters in foods.

In addition, this device has an integrated measurement data management system and wired and wireless connectivity features.

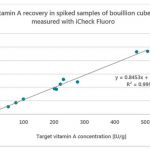

The first edition of iCheck Modular will provide an all-inclusive solution for the quality control of edible oil and its fortification. We also aim to produce environment-friendly, non-hazardous reagents that allow for a wide measurement range at one-tenth of the cost compared to traditional methods.

Other features of the iCheck Modular include;

Multiplex analytics through advanced optics design; absorption measurement of colorimetric analytes at different wavelengths; fluorometric measurement of analytes excited by wavelengths in the UV range; a sample preparation module; an incubator for sample preparation; heating and cooling function; control and data module; a touchscreen to control, record and monitor measurements; visualization, and tracking of measurement results against set targets, wired and wireless connectivity with iCheck Connect app; a remote maintenance option; a Camera module with clever camera design to capture sample ID, QR code, barcode, and sample label scanner.

iCheck Connect is our digital companion app that enables monitoring and visualization of data in a web and mobile app utilizing data transfer from our devices to benefit stakeholder groups at all levels.

Why our work is important

Food fortification is a cost-effective way to improve large populations’ nutrient intake, especially for those with limited access and affordability to diverse, nutrient-dense foods. But the ongoing fortification programs have several significant gaps in the availability of quality data and information regarding the coverage. As a result, around 200 million people miss the expected health benefits as current monitoring systems fail to ensure full fortification compliance.

Up to 80% of flour, edible oils, and salts do not contain the level of micronutrients they should by law. Moreover, around 60% of vitamin A is estimated to be lost along the value chain of fortified oil production. To make matters worse, up to 50% of the expected impact of fortification programs is lost due to a lack of monitoring and enforcement of regulations.

At BioAnalyt, we believe that accurate and timely testing of micronutrients is critical to impactful decision-making as we continue to work on solutions to improve these processes.

You can get more information about the WFP Innovation Accelerator Program here.

References:

- Nutrients 2020, 12(12), 3899; https://doi.org/10.3390/nu12123899

- Global Health: Science and Practice, 3(3):446-61 – DOI:10.9745/GHSP-D-15-00171