Did you know global vegetable oil production amounted to around 208.81 million metric tons in 2021/22?

In this Fortified Food Vehicles Series, our strategic partner and fortification Quality Assurance/Quality Control expert, Dr. Phillip Randall, outlines the rigorous steps and procedures every batch of edible oil undergoes before reaching local supermarkets.

In the first section, you will get an overview of major production steps commencing from crude oil to refined oil.

Overview

Very simplistically, large-scale refining of edible oils is a continuous batch process [3 main batch operations are Neutralise, Bleach, and Deodorise], with each batch operation having a ‘proceed or repeat’ decision step. Once the oil has finished the batch process steps, it can now be fortified in another batch process [batches can be 50 to 1,500 MT] or continuously as the batch is pumped to the finished product tanks.

Very simplistically, large-scale refining of edible oils is a continuous batch process [3 main batch operations are Neutralise, Bleach, and Deodorise], with each batch operation having a ‘proceed or repeat’ decision step. Once the oil has finished the batch process steps, it can now be fortified in another batch process [batches can be 50 to 1,500 MT] or continuously as the batch is pumped to the finished product tanks.

Quality Specifications

Sellers recognize that while “quality on board final” is the norm (and this ‘rule’ applies to all commodities), some negative deviation will occur even though environmental conditions are controlled on clean product tankers. Temperatures, for example, are optimized but could not be considered ideal – the oil must be kept fluid at all times; otherwise, it could not be pumped.

To this end, price adjustment is practiced. A consignment of crude palm oil may have a specified FFA (Free Fatty Acid) and M&I (Moisture and Insolubles) [1] with a minimum DOBI (Deterioration of Bleachability Index) value. DOBI is an analytical procedure [2] used to control crude palm oil quality.

The DOBI of palm oil indicates the sample’s oxidation rate and the ease of processing the palm oil. A higher DOBI value indicates the fruit is fresh, ripe, and free of contaminates. Bleaching earth is used with palm oils to refine the oil to an acceptable color as required by users and food manufacturers. The DOBI value gives the palm oil refiner information on what type of bleaching earth to use and how much is needed. The DOBI of palm oil can easily be determined using a spectrophotometer.

Individual traders will have their own ‘discounting’ system, but it all works based on “what will it cost the buyer to make the product meet the relevant in-country legislation?”. Tankers have been known to go up and down the coastline ‘hunting’ for a buyer, sometimes for a month or so; the oil on the tanker will constantly be deteriorating but always has a value if only for a low-end product like soap. So the question is how much it will cost me to refine this low-quality consignment.

Reality check

The vast majority of ‘crude oil’ shipped out of Malaysia, Indonesia, South America, and the USA, etc., is of such a quality [3], when delivered, that it would meet Codex Standard 210 ‘Standard for Named Vegetable oils’ requirement of the Appendix [not binding by Codex but often built into national standards] for quality parameters. The shipping documents will (unless it is packaged in retail packs) state that the consignment is a “crude” – even if it is ‘Crude, Refined, Bleached, Deodorized Oil’ (CRBDO), which meets Stan 210. This is a very commonly shipped commodity. It enters a country at zero tariff – refined oils carry 20 to 40% import [4] duties [5] – because it is ‘encouraging local industry.’ There is no guarantee the oil, when shipped, will meet Codex Stan 210 when delivered, so setting a ‘standard’ for ‘what is crude’ is superfluous, but refineries essentially ‘bet’ on getting a quality of such a standard [and the major exporters are experts at doing this as a matter of routine] that the actual refining process is virtually minimal. Importer refineries are increasingly looking to get CRBDO so that they get a 99% recovery vs. taking a ‘spot market’ consignment which may have an 80% (or at least significantly lower – these numbers are never discussed by industry) recovery. It is not unknown for an import to pass through the refinery to the finished product tanks without the benefit of firing up the boiler.

Refineries are configured in such a way as to make it ‘impossible [6]‘ to go from goods received to packaging or goods issuing without going through the refinery. All fortification systems are set up so that it is impossible for oil to be added to the system after the fortification process [this does not prove the fortification system was active, only that it went through it].

Neutralization |

Bleaching

The oil will remain in the process until the color criteria are met. The bleaching process essentially removes some color from the oil; reduces how much chlorophyll and carotenoids the oil contains; removes soap, gums, and trace metals; and decomposes oxidation products. Bleaching earth itself accounts for 5-10% of overall refining costs, depending on a variety of factors, including oil type, dosage, oil contaminant levels, specification, and disposal cost. Parameters monitored are FFA, Soap, Colour, Bleachability, and PV(Peroxide Value), all at high risk to the process. In addition, the flavor will now be checked – to ensure it is becoming ‘bland’. |

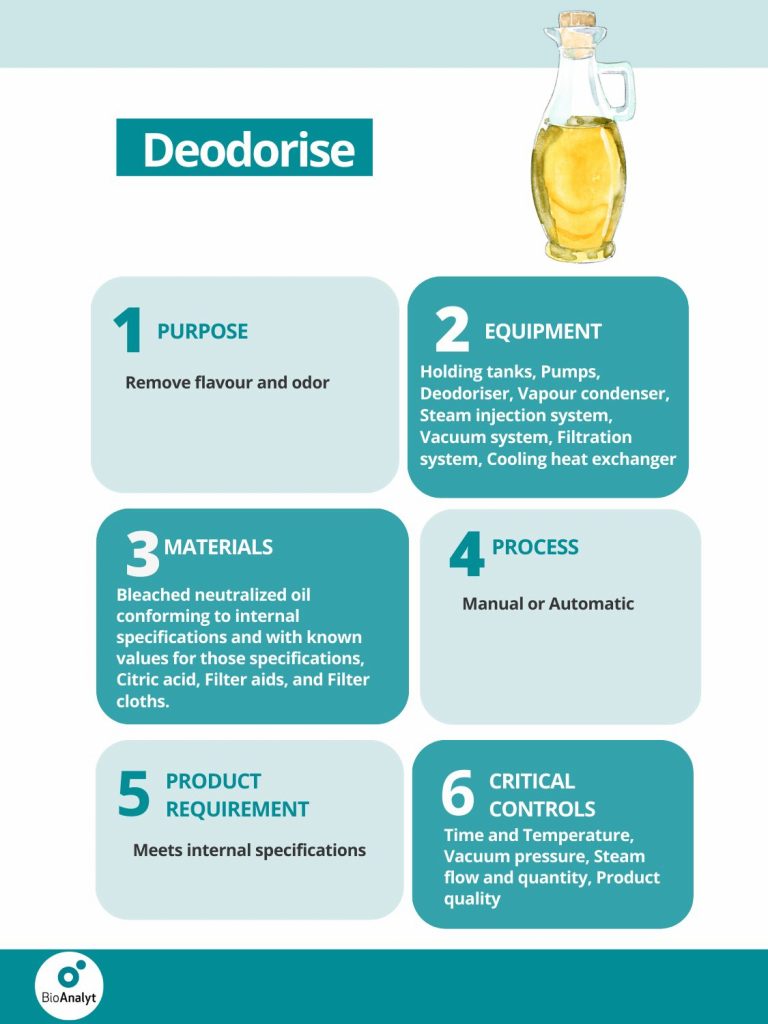

Deodorise

Parameters monitored are FFA, Soap, Colour, Bleachability, and PV, all at high risk to the process. In addition, the flavor will now be checked – to ensure it is becoming ‘bland.’ Oil – at this point – must be capable of meeting a national standard for generic cooking oil. |

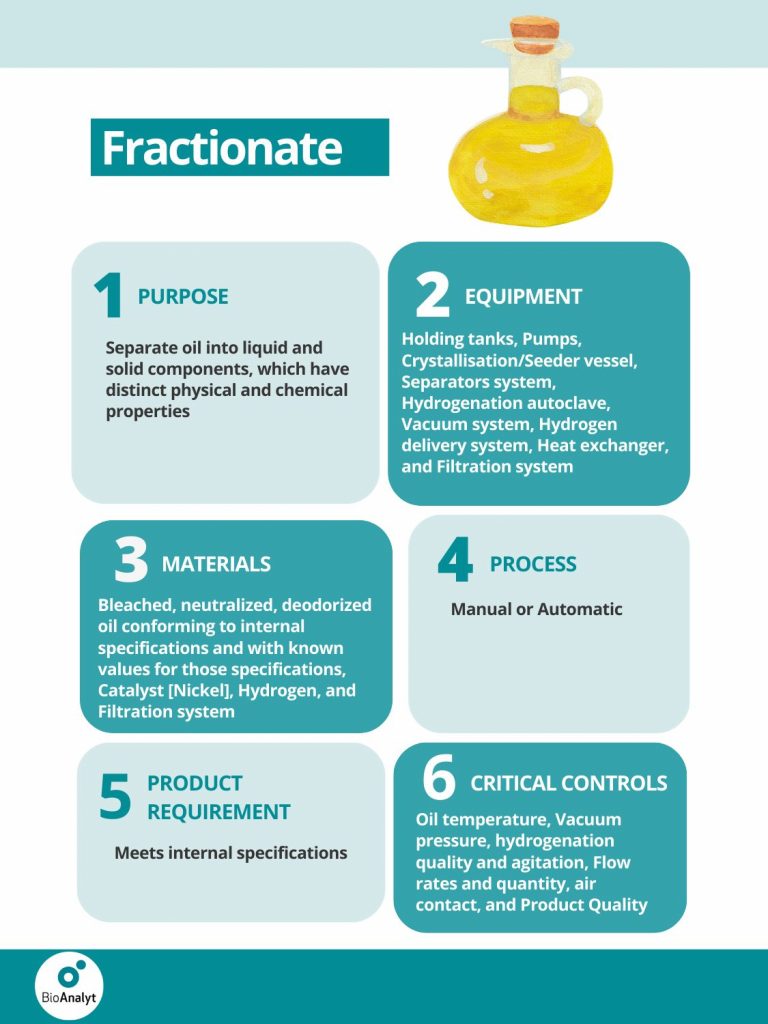

Fractionate

|

|

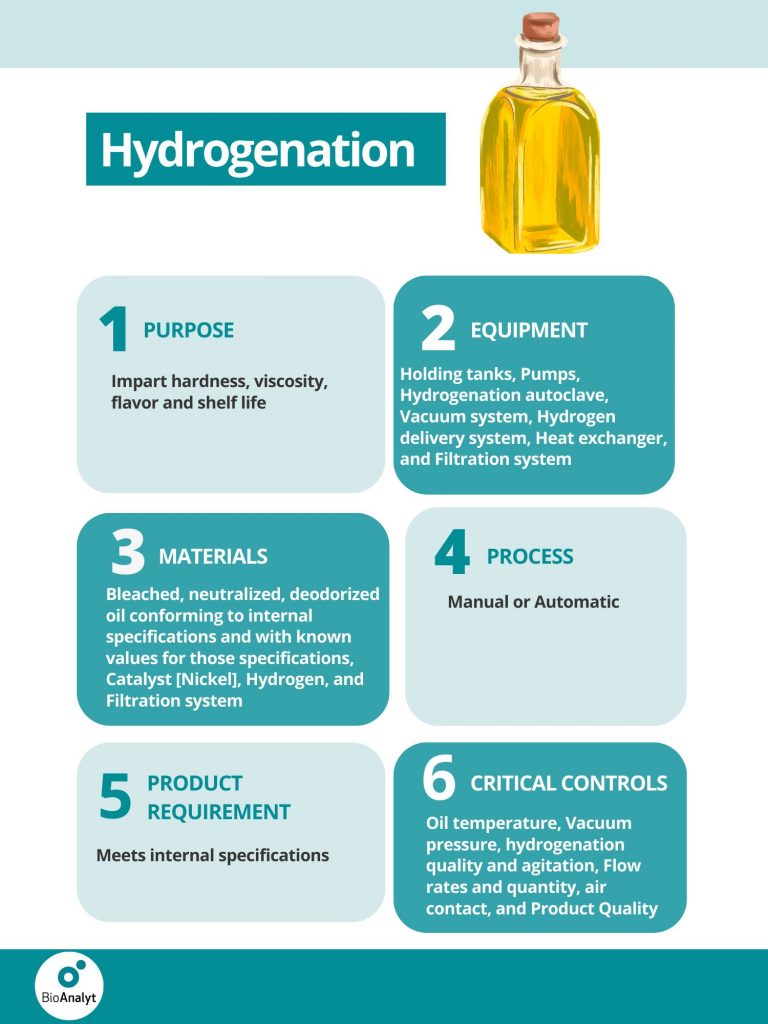

Hydrogenation

Parameters monitored are IV and Solids, both of which are high risk to the process and final quality. The flavor is a medium risk, and any change to PV is a high risk to the fortification process. The Nickel catalyst may be monitored – a low risk – but it is not unknown for refineries to add very small quantities of catalyst [9] and shortcut the hydrogenation process. |

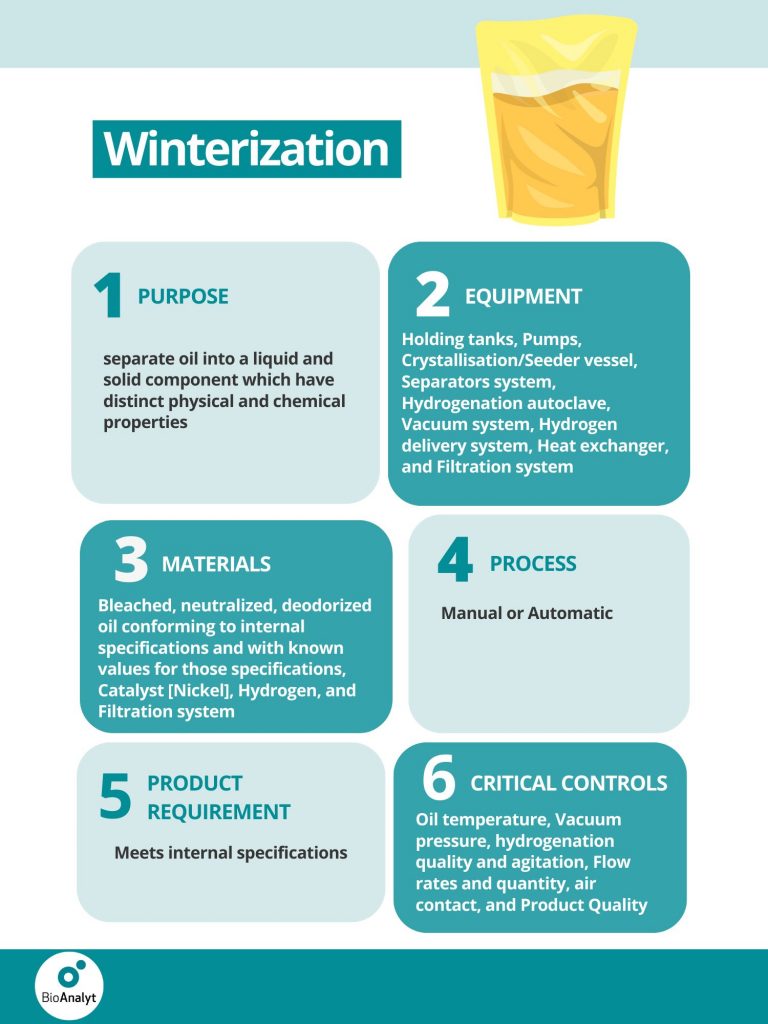

Winterization

Required, theoretically, in Rice Bran oil, common in sunflower oil. In lower technology countries, this may have been combined with a degumming process carried out by the supplier of the crude refined delivered product. |

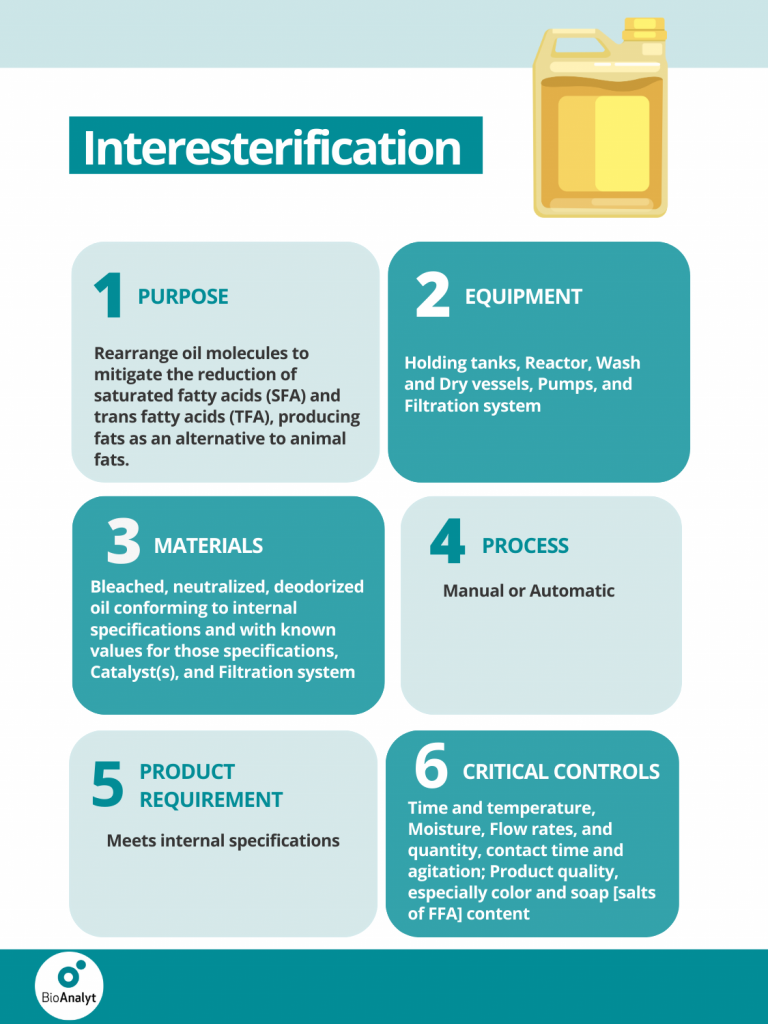

Interesterification

Parameters monitored are FFA, M&I, Colour, and Bleachability, all high risk to the process, and PV for risk to fortification. |

- [1] Moisture and Insoluble

- [2] https://assets.thermofisher.com/TFS-Assets/MSD/Application-Notes/SN53139-deterioration-bleachability-index-dobi-palm-oil-analysis.pdf accessed 19th August 2022

- [3] This is not exporters being altruistic – this gives the exporter the best chance of having a saleable product at the point of delivery

- [4] Legal protectionist tariffs

- [5] Significant on a USD1m outlay for 10,000 MT

- [6] ‘Impossible’ is defined as asking the Site Engineer hypothetical questions about how the product would/could be moved from point A to point B if the event of an unforeseen quality issue.

- [7] It is one of the reasons clear plastic containers are used in numerous countries; oil technologists know about the influence of UV on oil, which is why the outer packaging is opaque cardboard.

- [8] The color of Olive oil resonates strongly with higher-end (due to price) consumers, which is why adding ethylene glycol (anti-freeze) to sunflower oil catches so many ‘bargain hunters’ in that economic group.

- [9] The ‘proof’ of undergoing hydrogenation is a trace amount of a catalyst

Bleaching is a “Go/No Go” step with a duration difficult to predict (except in broad terms). While color is not the most technical reason for the process, it is the one demanded by the consumer who is increasingly insisting on a clear, bright, and, in many cases, colorless oil

Bleaching is a “Go/No Go” step with a duration difficult to predict (except in broad terms). While color is not the most technical reason for the process, it is the one demanded by the consumer who is increasingly insisting on a clear, bright, and, in many cases, colorless oil  Deodorization is another “Go/No Go” with a duration again difficult to predict. However, it is the last step in which basic end-use quality is determined for most edible oils. The oil will stay in the process until the product tastes smells, and looks correct according to the sensory inputs of the engineers. Then samples will be taken for confirmatory analysis.

Deodorization is another “Go/No Go” with a duration again difficult to predict. However, it is the last step in which basic end-use quality is determined for most edible oils. The oil will stay in the process until the product tastes smells, and looks correct according to the sensory inputs of the engineers. Then samples will be taken for confirmatory analysis. All of the parameters being measured are checked to maintain the final quality – a low risk – but PV remains a significant risk to fortification.

All of the parameters being measured are checked to maintain the final quality – a low risk – but PV remains a significant risk to fortification. Hydrogenation of vegetable oil has been a common practice for over a century. It was introduced to convert unsaturated fatty acids in vegetable oils and marine or animal fats to make them more stable for oxidation. In this process, unsaturated double bonds in the fatty acids of oil molecules react with hydrogen atoms in the presence of a catalyst. Commercial hydrogenation of edible oils uses nickel catalysts. Other catalysts, such as platinum, palladium, copper, etc., have also been applied in hydrogenation applications but are not used in the commercial hydrogenation of edible oils. Hydrogenation has been used to improve the oxidative stability of vegetable oils for improved shelf life and to modify the solids content and melting characteristics of the oil to formulate shortening and margarine products with the desired physical properties.

Hydrogenation of vegetable oil has been a common practice for over a century. It was introduced to convert unsaturated fatty acids in vegetable oils and marine or animal fats to make them more stable for oxidation. In this process, unsaturated double bonds in the fatty acids of oil molecules react with hydrogen atoms in the presence of a catalyst. Commercial hydrogenation of edible oils uses nickel catalysts. Other catalysts, such as platinum, palladium, copper, etc., have also been applied in hydrogenation applications but are not used in the commercial hydrogenation of edible oils. Hydrogenation has been used to improve the oxidative stability of vegetable oils for improved shelf life and to modify the solids content and melting characteristics of the oil to formulate shortening and margarine products with the desired physical properties. Winterization entails the fractional crystallization of oils and fats, which is then followed by the separation of solids to produce high-quality salad oils. To design an effective winterization process, it is critical to consider the cooling rate of oil, the temperature of crystallization, and the mobility of triglyceride molecules in the oil mass. These variables play a crucial role in separating solid fats as distinct crystals and facilitating their filtration from the oil.

Winterization entails the fractional crystallization of oils and fats, which is then followed by the separation of solids to produce high-quality salad oils. To design an effective winterization process, it is critical to consider the cooling rate of oil, the temperature of crystallization, and the mobility of triglyceride molecules in the oil mass. These variables play a crucial role in separating solid fats as distinct crystals and facilitating their filtration from the oil. Interesterification modifies fats and oils to create food ingredients for various applications. This method can reduce levels of saturated and trans fatty acids in certain foods, providing an alternative to animal fats or partially hydrogenated oils.

Interesterification modifies fats and oils to create food ingredients for various applications. This method can reduce levels of saturated and trans fatty acids in certain foods, providing an alternative to animal fats or partially hydrogenated oils.