At BioAnalyt, pets aren’t just part of our families; they’re part of our office life too. Dupree (Jonathan’s thoughtful sidekick), Brownie (Leona’s social butterfly), and Haily (Julius’s gentle soul) often brighten our workdays, reminding us why animal health and nutrition matter so much. Many of our colleagues also share their homes with cats, rabbits, hamsters, and guinea pigs. This love for animals is woven into our DNA after all, our founder, Professor Florian Schweigert, began his career as a veterinarian.

When it comes to pet food, nutrients are never “just ingredients.” Among them, vitamin A stands out as both essential and notoriously difficult to manage.

Why Vitamin A Is Critical and Risky in Pet Food

Vitamin A is a fat-soluble micronutrient with a major impact on vision, immune function, reproduction, and overall health. Deficiency can lead to serious health problems, including poor eyesight, weakened immunity, and reproductive disorders (1).

At the same time, excess vitamin A can be equally harmful, particularly for cats. Commercial guidelines define strict upper limits:

- Cats: 333,300 IU/kg

- Dogs: 250,000 IU/kg (3)

Liver one of the richest natural sources of vitamin A is widely used in wet pet food. However, its vitamin A content can vary dramatically depending on:

- Animal species

- Feeding regime

- Farm and region

- Individual animal differences (2)

Without systematic testing, this natural variability can introduce significant safety and compliance risks.

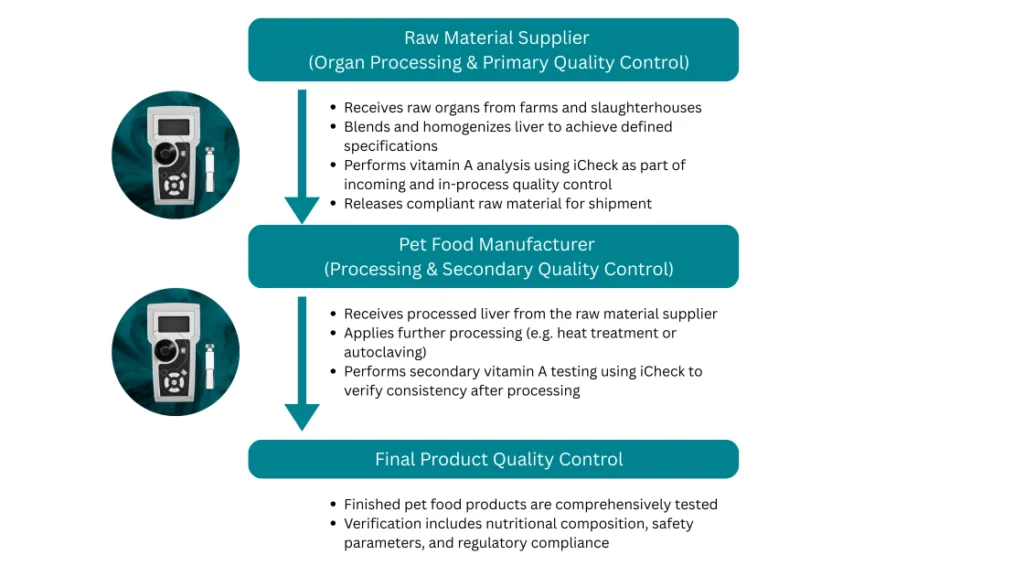

The Value Chain Challenge: From Raw Liver to Finished Pet Food

Managing vitamin A safely is not the responsibility of a single actor. It requires coordination across the entire value chain:

Each step benefits from rapid, reliable data to make informed decisions before costly processing or formulation errors occur. This is where on-site vitamin A testing has become an increasingly important tool.

Rapid Vitamin A Testing with iCheck Fluoro

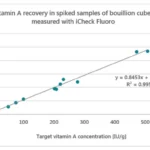

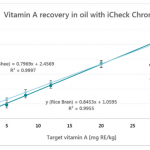

iCheck Fluoro is a portable fluorometer developed by BioAnalyt for fast, reliable vitamin A analysis in animal tissues such as liver.

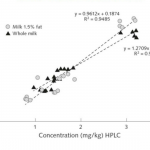

Unlike high-performance liquid chromatography (HPLC) the laboratory gold standard that is accurate but slow, expensive, and centralized iCheck Fluoro enables:

- Results within minutes

- Testing directly at supplier or factory level

- High correlation with HPLC reference methods

- Reduced delays, logistics, and analytical costs

BioAnalyt’s background lies in animal health and precision nutrition. iCheck devices are widely used to measure micronutrients in livestock blood and tissue samples, supporting optimized feeding strategies in dairy cattle, poultry, salmon, pork, and more. This scientific foundation made iCheck Fluoro a natural fit for pet food applications, where speed, traceability, and safety are critical.

Case in Point: Screening Liver Before It Enters Production

A leading global pet food producer introduced iCheck Fluoro as part of its raw material quality assurance system. The goal was clear: verify vitamin A levels in incoming liver batches before they enter production.

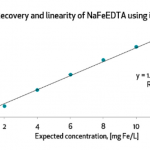

Key outcomes observed during method validation and routine use included:

- Significant variability in vitamin A levels across regions and suppliers

- Identification of occasional batches with exceptionally high vitamin A

- Strong agreement between iCheck Fluoro results and HPLC reference data

This enabled faster, more consistent decisions at the point where they matter most: raw material acceptance.

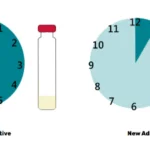

Smart Decision-Making When Results Vary

Rapid testing supports structured decision-making:

- Low vitamin A levels: Typically manageable through formulation and vitamin premix addition.

- High vitamin A levels: Trigger further evaluation, additional testing, or formulation review.

- Excessively high levels: Batches are rejected and excluded from production to ensure compliance and safety.

Strict traceability rules apply batches are never blended to dilute high values. This ensures transparency, regulatory compliance, and consumer trust.

The Role of BHJ: Quality Control at the Raw Material Supplier Level

A key player in this value chain is BHJ, a global supplier of animal-based ingredients including liver, meat, and organs, etc. for the pet food industry. BHJ supplies high-quality ingredients to major pet food producers and applies rigorous quality and safety standards across its operations.

A key player in this value chain is BHJ, a global supplier of animal-based ingredients including liver, meat, and organs, etc. for the pet food industry. BHJ supplies high-quality ingredients to major pet food producers and applies rigorous quality and safety standards across its operations.

As part of its quality assurance approach, BHJ uses BioAnalyt’s iCheck Fluoro to screen incoming livers for vitamin A content, ensuring that the raw materials will meet customer specifications before shipment. BioAnalyt works closely with BHJ across multiple production locations, supporting standardized testing and quality control processes in Denmark, Poland, Spain, Lithuania, Hungary, and Germany.

By testing at the supplier level, BHJ:

- Reduces downstream risk for pet food manufacturers

- Improves consistency of supplied ingredients

- Strengthens transparency and trust with customers.

“Vitamin A variability in livers is a known challenge in our industry. Rapid testing with iCheck Fluoro allows us to screen raw materials early and ensure they will meet our customers’ specifications, before they leave our facilities. This adds speed, confidence, and an extra layer of safety to the supply chain.”

– Agnieszka Zgubińska-Zabiciel, BHJ

Benefits for Pet Food Producers and Raw Material Suppliers

By integrating rapid vitamin A testing into quality control workflows, companies can:

- Verify vitamin A levels in liver within minutes

- Reduce reliance on slow, centralized laboratory testing

- Prevent costly production adjustments or recalls

- Strengthen supplier–manufacturer collaboration

- Demonstrate proactive risk management to regulators and customers

A Practical Tool for a Complex Nutrient

Vitamin A will always be a challenging nutrient essential, powerful, and variable by nature. What has changed is the ability to measure and manage it quickly, directly where decisions are made.

Vitamin A will always be a challenging nutrient essential, powerful, and variable by nature. What has changed is the ability to measure and manage it quickly, directly where decisions are made.

From raw material suppliers like BHJ to global pet food producers, iCheck Fluoro shows how practical science can improve safety, efficiency, and trust across the pet food value chain.

Read more about iCheck Fluoro measuring vitamin A in animal liver.

References:

- Shastak, Y., & Pelletier, W. Pet Wellness and Vitamin A: A Narrative Overview. 2024;14(7):1000. https://doi.org/10.3390/ani14071000

- S. Department of Agriculture. FoodData Central. 2021.

- American Association of Feed Control Officials Official Publication. Champaign, IL, USA, 2022.