More than 5 billion people worldwide lack adequate essential micronutrients, a burden felt most in Low- and Middle-Income Countries (LMICs) but still present in high-income countries (1). Food fortification is a cost-effective solution, yet many programmes still struggle to meet national standards due to weak enforcement systems, limited incentives, and manual, resource-intensive monitoring.

As countries seek more sustainable and accountable fortification systems, digital innovation is becoming increasingly essential. The Lighthouse Project, led by the Global Alliance for Improved Nutrition (GAIN) with BioAnalyt and other partners, integrates the DFQT+ (Digital Fortification Quality Traceability Plus) platform with tools like iCheck Modular and iCheck Connect to enable accurate, secure, and traceable data from factories to markets. This modernized approach strengthens oversight, builds producer accountability, and ensures fortified foods consistently meet quality requirements.

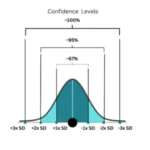

Fortification programmes often fall short because producers and regulators lack timely, reliable data, while enforcement and accountability remain weak. DFQT+ addresses these gaps by providing a country-owned, user-friendly digital system that captures, authenticates, and shares real-time fortification data. By linking rapid testing tools like iCheck with centralized monitoring, the platform enables more efficient compliance, reduces errors, and supports better decision-making from factory to market.

This article explores how the initiative is being piloted in Nigeria and Bangladesh, alongside insights from the DFQT+ Digital Lab Workshop in Lagos, showing how digital tools and hands-on capacity building are laying the foundation for stronger, more transparent fortification systems.

The Innovation: Digital Transformation in Food fortification

Micronutrient deficiencies remain a global health challenge, and delivering consistent fortification quality requires modernized monitoring systems. Through the DFQT+ Project (2022–2025), GAIN and its partners are piloting and scaling digital traceability solutions in Bangladesh, India, and Nigeria (2).

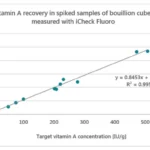

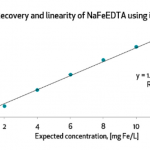

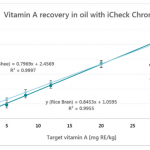

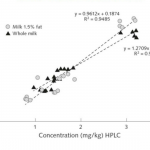

DFQT+ is designed to be adaptable, with its flexible design, DFQT+ can track quality and product information across various value chains, making it suitable for different food vehicles. By automating real-time data transfer such as Vitamin A measurements in edible oils it reduces manual errors, strengthens oversight, and supports both producers and regulators.

The goal is to establish a global standard that ensures fortified foods deliver the quality and safety communities rely on. For producers, this means improved product quality and reduced waste; for governments, stronger oversight and data-driven decision-making; and for families, fortified foods that reliably deliver the nutrients children need for healthy growth. BioAnalyt supports this transformation through iCheck Modular and iCheck Connect, helping make fortification more consistent, compliant, and effective.

Building Capacity Through the Lighthouse Project Digital Training: Nigeria and Bangladesh

The lighthouse Project, involving the incorporation of edge devices, is an aspect of the DFQT+ project. That is, integration of devices to automate data capture and sharing with DFQT+. As part of the Lighthouse Project, BioAnalyt is supporting national partners with hands-on digital training that integrates the iCheck Modular, iCheck Connect with the DFQT+ platform into daily workflows, building the capacity needed for accurate measurement, traceability, and compliance in fortified foods.

In Nigeria, a four-day pilot training in August 2025 hosted by GAIN, TechnoServe and BioAnalyt collectively at the Standards Organisation of Nigeria (SON). This event brought together over 20 participants from food producers, private labs, and regulatory authorities. Led by BioAnalyt experts Mr. Mridul Kathed and Dr. Leona Kovac, the programme combined classroom sessions in Lagos with on-site onboarding at NAFDAC (National Agency for Food and Drug Administration and Control), WASIL (West African Soy Industries Limited), PZ Wilmar, and the AQAC (African Quality Assurance Centre). All the participants received hands-on training in measuring Vitamin A in edible oils, transferring results via iCheck Connect, and linking data to DFQT+ for full traceability.

“I’m confident this new expertise will contribute to my organization’s success, and I look forward to applying it in future projects,” shared Mr. Rufai Habeeb Ademola, an iCheck user during the onboarding visits at WASIL.

In Bangladesh, a two-day onboarding session in Dhaka in September 2025 brought together participants from SEOI (Sena Edible Oil Industries), icddr,b (International Centre for Diarrhoeal Disease Research, Bangladesh), BSTI (Bangladesh Standards and Testing Institution), the Bangladesh Food Safety Authority, DNCRP (Directorate of National Consumer Rights Protection), and GAIN. Led by Mr. Mridul Kathed, attendees learned to operate iCheck Modular devices for Vitamin A testing, practiced with fortified oil samples, and managed results digitally through iCheck Connect linked to DFQT+. Open discussions highlighted how digital tools can improve efficiency, accountability, and compliance in fortification monitoring.

By embedding these systems in Nigeria and Bangladesh, the Lighthouse Project is strengthening national capacity and laying the groundwork for more consistent fortification quality helping ensure fortified foods deliver their intended health benefits.

The DFQT+ Digital Lab Workshop in Lagos

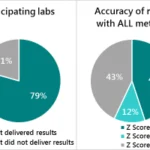

As DFQT+ moves from pilot to scale-up, the Digital Lab, an annual workshop organized by TechnoServe and GAIN for the DFQT+ program in Lagos brought regulators, producers, and partners together to align on how the platform can strengthen fortification quality and traceability. The event aimed to demonstrate DFQT+ as a practical, scalable tool for improving oversight and ensuring that data flows seamlessly from premix procurement to production and nutrient testing.

Participants explored real-time data dashboards, discussed system features, and shared feedback to support wider national adoption. As Babajide Ogunleye from TechnoServe, a fortification specialist supporting the initiative explained, “The goal was to bring stakeholders together and show that DFQT+ is a practical solution for improving traceability and regulatory oversight.”

Progress so far has strengthened confidence in the platform. “We’ve seen a clear increase in trust in digital fortification data,” he noted, adding that, with the DFQT+ system, regulators can now make quicker decisions and conduct more targeted inspections. There is strong momentum for national scale-up, supported by regulatory agencies and positive results from the pilot.

Looking ahead, integrating rapid tools like BioAnalyt’s iCheck will further improve real-time decision-making. “With the iCheck Modular, producers can generate immediate results and feed them directly into the system; this solves a major bottleneck,” he shared. Testing at multiple points in production is already strengthening compliance and helping ensure consumers receive properly fortified foods.

A Global Vision

Introducing digital tools into the food fortification landscape is transforming quality standards and, ultimately, improving the health of those who benefit from fortified foods.

What is being piloted today offers a glimpse of the future: fortified foods supported by digital solutions that are faster, more reliable, and more accountable. Step by step, these innovations are laying the groundwork for healthier generations and a world where good nutrition is accessible to all.

As part of the Lighthouse Project, BioAnalyt is committed to expanding its reach and collaborating with industries, partners, and government bodies to ensure our devices and solutions help fortify food not just better, but right.

Would you like to learn more about iCheck Modular or explore how our products can be integrated into your quality monitoring process? Connect with us today!

References:

- Passarelli S, Free CM, Shepon A, Beal T, Batis C, Golden CD. Global estimation of dietary micronutrient inadequacies: a modelling analysis. Lancet Glob Health. 2024;12:e1590–e1599. doi:10.1016/S2214-109X(24)00276-6.

- Global Alliance for Improved Nutrition. (n.d.). Digital Fortification Quality Traceability Plus (DFQT+): Developing country-driven digital systems for improving large scale food fortification quality and more. GAIN. https://www.gainhealth.org/digital-fortification-quality-traceability