In Tanzania, vitamin A deficiency remains one of the most urgent yet overlooked nutrition challenges, affecting more than one-third of children under five and women of reproductive age [1]. This deficiency not only threatens vision but also weakens immune defences, hampers brain development, and increases the risk of maternal and child mortality. Even mild deficiencies impair school performance and reduce adult productivity, perpetuating cycles of poverty [2,3].

Edible oil fortification with vitamin A offers an accurate and cost-effective food-based approach for mitigating vitamin A deficiency, as edible oil provides a conducive environment for the bioavailability of vitamin A within the body [4]. However, scaling up of edible oil fortification among small and medium enterprises (SMEs) requires capacity building in Good Manufacturing Practices (GMP), particularly quality assurance and quality control processes and Good Hygienic Practices (GHP).

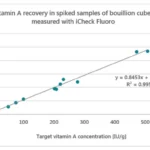

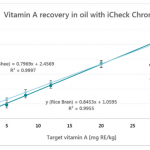

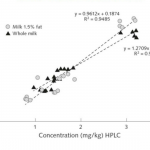

To achieve this, BioAnalyt provides iCheck devices that allow millers to accurately measure vitamin A levels in edible oil. Alongside this, BioAnalyt’s training and capacity-building efforts help SMEs comply with national fortification standards and thus improve the health of the people of the United Republic of Tanzania.

This article explores the Tanzanian landscape of vitamin A fortification, focusing on the role of TASUPA (Tanzania Sunflower Processors Association) and the contributions of BioAnalyt in advancing locally owned solutions to hidden hunger.

A Local Solution Takes Root

Since 2011, Tanzania has had a mandatory legislation requiring large-scale producers of edible oils, among other staple food vehicles, to fortify with vitamin A under the Food Fortification Regulations, 2011 (5). However, these regulations originally exempted small-scale and medium-scale manufacturers (5).

Large-scale refined oil producers have dominated much of the fortified oil market. For example, by about 2015, 14 large-scale producers (including vegetable oil refineries) accounted for about 80% of the fortified edible oil market share (6). Despite mandatory fortification, only about 16% of all edible oil in Tanzania met the required standards for adequate fortification (7).

In contrast, Tanzania has a substantial number of SMEs and small-scale oil and maize millers, especially in rural areas, which reach a large share of the population. Projects like MASAVA have shown that SMEs can fortify unrefined sunflower oil technically and commercially, enabling reach to retailers across Manyara and Shinyanga, serving vulnerable groups (lactating mothers, young children) who are often underserved by large urban-based refined oil supply chains (8).

As of recent policy reforms (2024/2025), the fortification regulation has been broadened to also apply to small and micro producers, making fortification of edible oil, maize flour, and wheat flour mandatory at all levels of production. This should allow SMEs to legally fortify oil and reach more of the population (9).

TASUPA: Organizing Change from the Ground Up

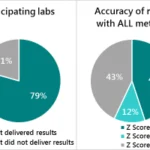

At the heart of Tanzania’s fortification journey stands the Tanzania Sunflower Processors Association (TASUPA). Based in Dodoma, TASUPA unites more than 800 small and medium-sized oil millers, forming the backbone of the country’s decentralized sunflower oil industry. By 2026, when the government’s new regulation makes fortification of all edible oil mandatory, TASUPA aims to ensure that they and their members are fully prepared.

“Recognizing the challenge ahead, TASUPA reached out to Millers for Nutrition in 2024 for fortification support,” explains Mr. Patrick Mafunda, Senior Food Fortification Specialist, Millers for Nutrition, IGNITE TechnoServe. “Together with TechnoServe, Millers for Nutrition supports TASUPA with compliance, technical training, and guidance.”

Currently, only about 20% of TASUPA’s members operate mills with refining capacity, and these are the facilities that can carry out fortification. The remaining ~80% are small mills that produce crude oil only. Under TASUPA’s model, these smaller mills will continue supplying crude oil to the 20% large refineries, where the oil will be refined and fortified with vitamin A before reaching consumers. This structure ensures that even small processors remain part of the value chain while still meeting the national fortification standard.

To support this transition, TASUPA is pursuing a comprehensive strategy. A central part of this is the establishment of an association-run laboratory. Beyond vitamin A analysis, the lab will also conduct broader quality control testing, such as free fatty acids, peroxide value, and moisture content, thereby improving product quality across the sector. TASUPA also plans to repackage premix into smaller, more affordable units (e.g., one-litre packs) for distribution to members and to introduce robust quality monitoring systems to verify compliance. Together with partners like Millers for Nutrition and TechnoServe, TASUPA is also delivering targeted training for refinery owners who are new to fortification.

During a recent presentation session, TASUPA members also benefited from BioAnalyt’s presentation on rapid vitamin A testing technologies. Francis Millinga from the Tanzania Food and Nutrition Centre (TFNC) played a crucial role by providing translations and delivering a hands-on demonstration of the iCheck Chroma 3 device, strengthening members’ technical understanding and capacity for quality monitoring.

BioAnalyt’s Role: Enabling Quality Assurance

Reliable, accessible tools are important for supporting vitamin A monitoring across Tanzania’s small and medium-sized sunflower oil mills. BioAnalyt’s iCheck Chroma 3 devices allow TASUPA members to:

- Quickly check vitamin A levels in fortified oil at the mill or refinery.

- Support TASUPA’s hub-and-spoke model by providing simple, on-site verification of fortification efforts.

By providing these tools, BioAnalyt is empowering a sustainable solution to strengthen the quality of fortified oil. During the recent edible oil

fortification training for TASUPA SMEs in Tanzania, the presentation and technical contributions on fortified oil quality control and the use of the iCheck Chroma 3 device were very well received by the participants. Usually, BioAnalyt’s support doesn’t stop with technology. The team trains SME processors on quality control and practical use of iCheck deices, equipping them with skills and confidence to begin fortification.

As expressed by Mr. Ringo Iringo, the chairman of TASUPA: “BioAnalyt’s training is expected to have a significant and lasting impact on our processors by building their confidence as they prepare to begin fortification. It will also support compliance with fortification regulations, increase the availability of fortified cooking oil to the public, and ultimately contribute to reducing maternal mortality and improving child health.” Together, TASUPA and BioAnalyt are making fortified oil not just a policy goal, but a reality for Tanzanian families.

Overcoming Technical Challenges

Fortification of sunflower oil produced by SMEs presents specific technical considerations. While regulations require that only refined oil be fortified, many TASUPA members currently produce crude oil, which is often supplied to refineries for further processing. Approximately 15% of the sunflower oil produced by TASUPA members is refined and reaches local markets, where fortification is feasible.

To support SMEs in meeting the new nationwide requirement for fortified edible oil by 2026, the government has provided a grace period, along with grants to facilitate premix sourcing and access to essential equipment, such as iCheck devices for vitamin A verification. These measures aim to help small and medium-sized millers gradually comply with the regulation and integrate into the fortified oil value chain.

Distribution and Consumer Impact

Fortified sunflower oil is expected to reach consumers in a variety of packaging formats, including 1, 2, 3, 5, and 20-liter containers, with the potential for 0.5-liter packs to be sold in supermarkets. This flexible approach ensures accessibility across different economic segments. The Tanzanian government leads consumer education campaigns, deploying village health workers and nutritionists to educate communities about fortified oil benefits and encourage the shift from crude to fortified refined oil consumption.

A Model for Sustainable Development

Tanzania oil fortification program represents more than a nutrition intervention. It’s a blueprint for sustainable, locally owned development. Addressing hidden hunger requires a coordinated approach that combines regulatory mandates, practical technical solutions, and partnership-driven support. In the case of sunflower oil fortification in Tanzania, this involves national fortification requirements, community-based processing networks through TASUPA millers, tools like BioAnalyt’s iCheck devices for on-site vitamin A verification, and comprehensive training and guidance from partners such as Millers for Nutrition and TechnoServe. Together, these elements help ensure that small and medium-sized producers can comply with regulations and that fortified oil reaches vulnerable populations.

As highlighted by economic evaluations, every $1 invested in food fortification is estimated to generate about $27 in economic return, via averted disease, improved earnings, and enhanced work productivity [10]. The WHO emphasizes that vitamin A is important for visual health, immune function, and fetal growth and development, underscoring the critical role that fortification programs play in maternal and child health outcomes [11].

As Tanzania approaches the 2026 mandatory fortification deadline, the collaboration between partners such as Millers for Nutrition, TechnoServe, industry partners such as BASF and BioAnalyt, supported by government guidance, offers a strong model for addressing micronutrient deficiencies. This partnership combines technical expertise, on-the-ground training, access to fortification premix and equipment, and regulatory support to help small and medium-sized producers comply with fortification requirements and improve the availability of vitamin A fortified sunflower oil.

By empowering local solutions with the right technology and support, we’re not just fighting hidden hunger. We’re building the foundation for healthier, more prosperous communities across Tanzania.

Want to know how iCheck Chroma 3 can help ensure you’re fortifying the right amount of micronutrients in staple foods? Connect with us today to learn more.

References:

- Gebrekidan, A., Asgedom, Y., Woldegeorgis, A., Kassie, G., Haile, D., Damtew, Z., Teklay, Y., & Ayele, H. (2024). Vitamin A supplementation status and associated factors among children aged 6–59 months in Tanzania: A multilevel analysis. BMC Nutrition, 10(1), 24. https://doi.org/10.1186/s40795-024-00952-4

- Estimating food consumption, micronutrient intake and the contribution of large-scale food fortification to micronutrient adequacy in Tanzania. (2024). Public Health Nutrition, 27(4), 709–721. https://doi.org/10.1017/S1368980023002315

- HarvestPlus. (2023). Scaling up adoption of nutrient-dense foods in schools and communities in Tanzania. HarvestPlus. https://www.harvestplus.org/scaling-up-adoption-of-nutrient-dense-foods-in-schools-and-communities-in-tanzania/

- Ashraf SA. Food fortification as a sustainable global strategy to mitigate micronutrient deficiencies and improve public health. Discover Food. 2025 Jul 1;5(1):201.

- Tanzania Food, Drugs and Cosmetics (Food Fortification) Regulations, 2011, Government Notice No. 205. Ministry of Health / Tanzania Food and Drugs Authority. Retrieved from https://www.scribd.com/document/863984054/TZA-2011-Food-Fortification-Regulations-1

- Helen Keller International, et al. (2017). Large-scale wheat flour fortification programme increases plasma folate levels among women of reproductive age in urban Tanzania. Maternal & Child Nutrition, 13(1), e12261. https://doi.org/10.1111/mcn.12261

- Aaron, G. J., Friesen, V. M., Jungjohann, S., Garrett, G. S., Neufeld, L. M., & Myatt, M. (2017). Coverage of large-scale food fortification of edible oil, wheat flour, and maize flour varies greatly by vehicle and country but is consistently lower among the most vulnerable: Results from coverage surveys in 8 countries. The Journal of Nutrition, 147(5), 984S–994S. https://doi.org/10.3945/jn.116.243564

- MASAVA project. (2018). Promoting locally fortified sunflower oil with e-vouchers in Manyara and Shinyanga regions, Tanzania. International Development Research Centre. Retrieved from https://idrc-crdi.ca/en/research-in-action/promoting-locally-fortified-sunflower-oil-e-vouchers

- Tanzania officially launches new regulation to combat malnutrition: All flour millers to fortify. (2025, January 25). The Citizen. Retrieved from https://www.thecitizen.co.tz/tanzania/supplement/tanzania-officially-launches-new-regulation-to-combat-malnutrition-all-flour-millers-to-fortify-5012392

- Gates Foundation. (n.d.). How food fortification can impact millions in a cost-effective way. Retrieved from https://www.gatesfoundation.org/ideas/articles/food-fortification-to-fortify-the-future Gates Foundation

- World Health Organization. (2023, August 9). Vitamin A fortification of staple foods. Retrieved from https://www.who.int/tools/elena/interventions/vitamina-fortification